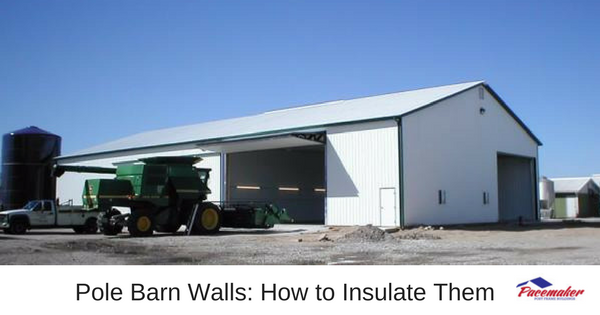

Whether for storage, animal shelter or other purposes, pole barns built with post frame construction methods are the most efficient way to erect a building that provides a large, uninterrupted space. Besides agricultural structures, post frame construction is regularly used for fire stations and warehouses that need substantial square footage without vertical beams to break up space.

Whether for storage, animal shelter or other purposes, pole barns built with post frame construction methods are the most efficient way to erect a building that provides a large, uninterrupted space. Besides agricultural structures, post frame construction is regularly used for fire stations and warehouses that need substantial square footage without vertical beams to break up space.

Energy Efficiency

In addition to the cost savings from planning, construction, materials and labor, post frame buildings are more energy efficient than standard construction. A properly insulated post frame structure requires approximately 15-20% less energy to maintain a constant temperature than a fully insulated, traditional structure.

The rationale for better efficiency with post frame construction is in the details of the design. With a standard stud-design buildings, the studs or vertical supports are 16 to 24-inches apart. With post frame, the vertical supports are wooden or steel posts spaced between 8 and 10-feet apart. As a result, insulating materials for the post frame building does not have as many energy-losing seams and spaces. The insulating material can be installed more uniformly. The installation of the insulation is much simpler also.

How to Insulate a Pole Barn or Post Frame Building

Since the spacing of the vertical supports is directly related to the efficiency of the insulation, less “interruption” in the wall cavity means the insulation will perform better.

The amount and extent of insulation required depends on your intended use for the building. The more constant you want the inside temperature to remain, the more insulation material may be required. There may be no reason to over-insulate unless you expect the purpose of the building to change at some point. It is best to insulate at the time of construction.

Plan ahead and work with experts to define the right insulation and ventilation requirements. Elimination of moisture is an essential design element to complement proper insulation.

Insulation Material

The most common insulation comes in fiberglass batt or blown fiberglass particles. Blown material requires special techniques and equipment, while batted material is far simpler to install.

A more expensive option is blown foam that is usually applied by a trained expert.

Two Insulation Approaches

One approach is to install six inches of insulation between each vertical wall member and cover with a moisture barrier, like Tyvek. This process is also appropriate for the ceiling surface. Insulating in this manner is possible at any time after the building shell is constructed. Adding an interior framed wall over the insulation further secures and insulates while providing a more finished interior.

Another option is to add just 2” of insulation material directly under the outer surface, which is often metal. This application reduces the amount of insulation required and can provide a similar R-value while deadening the sounds from outside. This method should be applied during construction.

Want to know if a post frame building is right for your project? Contact us or call!